What Is a Welding Table?

A Welding Table is a specialized work surface designed to support welding, fabrication, and assembly tasks with precision and stability. Unlike ordinary workbenches, a welding table is engineered to withstand high temperatures, heavy loads, and repeated mechanical stress while maintaining flatness and alignment.

In modern fabrication environments, a welding table plays a critical role in improving weld accuracy, efficiency, and overall work quality. For industrial users, consistent production quality and manufacturer-level control are essential, especially when welding tables are supplied in bulk for workshops or production lines.

The Purpose of a Welding Table

The main purpose of a Welding Table is to provide a stable, flat, and heat-resistant platform for welding operations. It allows operators to position workpieces accurately, clamp components securely, and maintain consistent alignment throughout the welding process.

By reducing movement and distortion, a welding table helps improve weld consistency and minimizes rework. In production environments, this directly contributes to higher efficiency and better output quality.

How a Welding Table Works in Practice

How a Welding Table Works in Practice

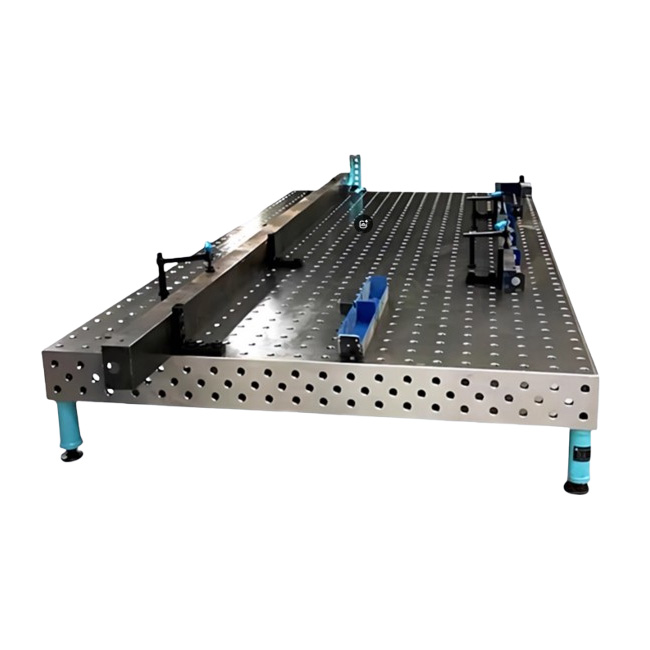

A Welding Table works by combining a rigid structure with a precisely machined surface. The tabletop is typically made from steel or cast materials that resist deformation under heat and load. Many designs include grid patterns or evenly spaced holes that allow for flexible clamping and fixturing.

During welding, the table absorbs and distributes heat while maintaining dimensional stability. This controlled behavior is especially important in repetitive production tasks, where consistency across multiple parts is required.

Key Features of a Welding Table

A well-designed Welding Table usually includes the following features:

·High flatness for accurate positioning

·Strong load-bearing capacity

·Heat and spatter resistance

·Modular clamping or fixture compatibility

These features allow the welding table to adapt to different fabrication needs, from simple repairs to complex assemblies.

Common Types of Welding Tables

Welding tables are available in several common configurations:

Fixed Welding Tables

Designed for stationary work, these tables provide maximum rigidity and are often used in heavy fabrication.

Modular Welding Tables

These tables allow interchangeable fixtures and extensions, making them suitable for flexible production environments.

Mobile Welding Tables

Equipped with wheels or adjustable bases, mobile tables support dynamic workshop layouts.

Each type serves different operational needs, but all rely on precise production standards to ensure reliability.

Applications of Welding Tables

Welding Table solutions are widely used in:

·Metal fabrication workshops

·Automotive and trailer assembly

·Structural steel fabrication

·Manufacturing and industrial production lines

In these applications, welding tables support repeatable processes and consistent output, making them essential for professional fabrication work.

Manufacturing and Production Considerations

Producing a high-quality Welding Table requires careful control of material selection, machining accuracy, and structural design. Flatness tolerance, surface hardness, and frame rigidity all influence performance and service life.

From a manufacturing perspective, standardized production processes help ensure that each welding table meets the same performance requirements. For buyers sourcing in bulk, stable production capacity and consistent quality are key factors when evaluating suppliers.

Why Manufacturer-Level Supply Matters

Industrial users often require multiple welding tables with identical specifications. Manufacturer-level production supports repeatability, traceability, and long-term availability.

Bulk supply capabilities also help reduce lead times and ensure compatibility across different workstations. This is particularly important for factories and fabrication centers that rely on standardized tooling.

Maintenance and Long-Term Use

Proper maintenance extends the life of a Welding Table. Regular cleaning, surface inspection, and protection against corrosion help preserve flatness and functionality.

Avoiding excessive impact loads and following recommended usage guidelines can further reduce wear. With correct care, a professionally produced welding table can remain reliable for many years.

Final Thoughts on Welding Table

A Welding Table is more than just a work surface—it is a foundational tool for precision, safety, and efficiency in welding and fabrication. Its ability to support accurate positioning and stable welding conditions makes it indispensable in both small workshops and large-scale production environments.

As fabrication demands continue to grow, the importance of reliable welding table production, controlled manufacturing processes, and dependable bulk supply will remain central to meeting industrial needs.

References

GB/T 7714:Cary H B. Modern welding technology 5/e[J]. Industrial Robot: An International Journal, 2004, 31(4): 376-376.

MLA:Cary, Howard B. "Modern welding technology 5/e." Industrial Robot: An International Journal 31.4 (2004): 376-376.

APA:Cary, H. B. (2004). Modern welding technology 5/e. Industrial Robot: An International Journal, 31(4), 376-376.