In modern industrial machinery, reliable power transmission is essential for maintaining efficiency, safety, and equipment lifespan. One critical component in this process is the Grid Coupling, a flexible mechanical device designed to connect two rotating shafts and transmit torque smoothly.

Unlike rigid connections, a Grid Coupling absorbs shock loads, compensates for misalignment, and minimizes vibration during operation. This makes it widely used in conveyors, pumps, compressors, fans, mining machines, and other heavy-duty systems. With advanced production technology and factory-level manufacturing, industrial grid coupling solutions today are built to handle high torque and demanding operating conditions while maintaining stability.

As a professional Grid Coupling Manufacturer, large-scale factory production ensures consistency, dimensional accuracy, and long service life for industrial applications.

What Is a Grid Coupling?

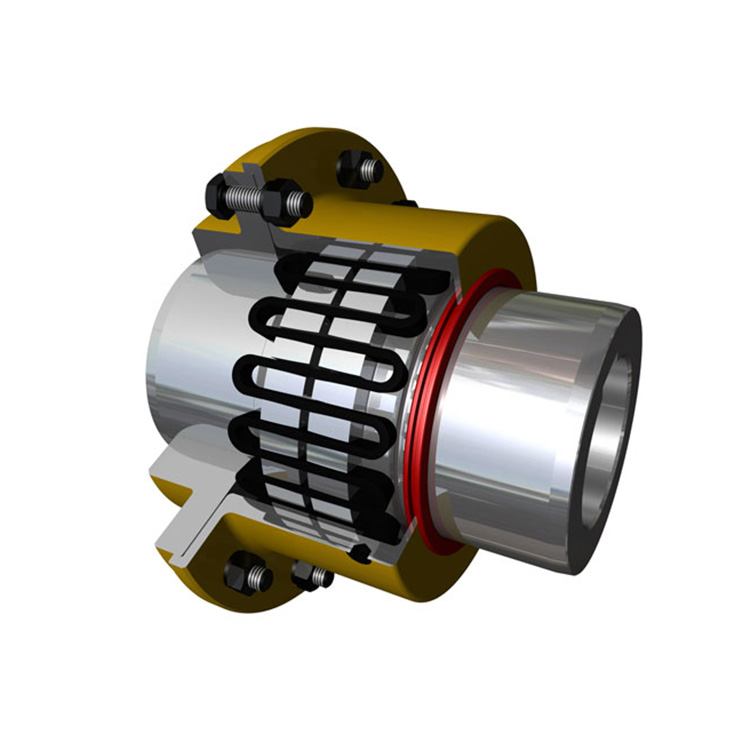

A Grid Coupling, also known as a Spring Grid Coupling, is a flexible shaft coupling that uses a serpentine-shaped spring grid element fitted between two hub halves. These hubs have precision-machined grooves where the grid sits and transfers torque from one shaft to another.

The grid element works as the elastic transmission medium. When torque is applied, the spring grid deforms slightly inside the grooves, allowing the coupling to absorb vibration and reduce shock loads. Compared with rigid couplings, this design protects connected equipment from excessive stress.

Industrial grid coupling production focuses on high-strength alloy materials, precision machining, and controlled heat treatment to ensure excellent load capacity and fatigue resistance.

How Does a Grid Coupling Work?

The working principle of a Grid Coupling is based on elastic engagement. When the driving shaft rotates, torque is transmitted through the coupling hubs to the spring grid. The grid’s curved profile distributes load evenly along the groove surfaces.

During operation, the grid element:

·Absorbs impact caused by sudden load changes

·Compensates for angular, axial, and radial misalignment

·Reduces vibration transmission

·Protects bearings and gearboxes from peak stress

For example, in a T20 Grid Coupling, the grid is optimized for higher torque transmission while maintaining flexibility. Factory-controlled production processes ensure that each grid fits precisely into hub grooves, maintaining smooth power transfer even under continuous operation.

This design allows Grid Coupling systems to perform reliably in both steady-state and start-stop industrial environments.

Key Components of a Grid Coupling

A typical Industrial Grid Coupling consists of several important parts:

1. Hubs

The hubs are mounted on the shafts and provide the main structural support. They are usually manufactured from high-strength steel through controlled production machining.

2. Spring Grid Element

This serpentine spring is the core of torque transmission. It flexes under load, offering shock absorption and vibration damping.

3. Cover and Seal

The cover protects internal components from dust and moisture while retaining lubrication. Factory assembly ensures sealing reliability for long-term use.

4. Lubrication System

Proper lubrication minimizes wear and improves heat dissipation, increasing service life for industrial grid coupling production units.

Each component is produced and inspected in a manufacturing factory environment to guarantee dimensional accuracy and performance stability.

Advantages of Using Grid Coupling

Using a Grid Coupling in power transmission offers multiple technical and economic advantages:

·High Torque Capacity – Suitable for heavy-duty machinery and continuous production lines.

·Shock Load Protection – Absorbs sudden impacts during startup and shutdown.

·Misalignment Compensation – Handles angular, radial, and axial offset between shafts.

·Reduced Maintenance – Protects bearings, seals, and gearboxes from premature failure.

·Long Service Life – Factory-quality materials and precision production improve durability.

Because of these advantages, many industrial users choose Industrial Grid Coupling Manufacturer solutions for critical power transmission systems.

Typical Applications of Industrial Grid Coupling

Grid Couplings are widely applied in various industries:

·Conveyor systems

·Mining and quarry equipment

·Pump and fan drives

·Compressors

·Steel and cement production lines

·Bulk material handling machinery

In high-load environments, T20 Series Grid Coupling models are often selected for their balance between flexibility and torque capacity. With professional factory production, these couplings can operate reliably under continuous vibration and heavy shock conditions.

Grid Coupling vs Other Coupling Types

Compared with rigid or rubber-based couplings, a Grid Coupling offers better performance in industrial conditions:

·Rigid couplings transmit vibration directly to equipment.

·Rubber couplings wear faster under heavy torque.

·Grid Couplings combine strength with elastic flexibility.

This makes them ideal for industrial power transmission systems requiring both durability and vibration control. Manufacturer-level production ensures consistent quality across bulk supply orders.

Manufacturing and Production Quality

The performance of a Grid Coupling depends heavily on manufacturing quality. A professional Grid Coupling Manufacturer and Factory Production system focuses on:

·Precision CNC machining

·Heat treatment control

·Grid spring forming accuracy

·Assembly inspection

·Load testing before shipment

Large-scale production facilities can supply consistent batches for global industrial projects. Factory production also enables customization for shaft size, torque rating, and application environment.

This production capability ensures that industrial grid coupling solutions meet both performance and safety requirements.

Choosing the Right Grid Coupling

When selecting a Grid Coupling, consider:

·Torque requirement

·Shaft diameter

·Operating speed

·Misalignment tolerance

·Environmental conditions

A reliable manufacturer will provide technical support during selection and offer stable factory production for bulk supply needs. Choosing the correct coupling helps improve system efficiency and reduce downtime.

Conclusion: Why Grid Coupling Matters in Power Transmission

A Grid Coupling plays a vital role in modern power transmission by delivering torque while protecting machinery from shock, vibration, and misalignment. With its spring-based elastic design, it improves equipment reliability and extends service life.

Supported by professional Manufacturer experience and Factory Production capability, industrial grid coupling solutions offer stable performance for heavy-duty applications worldwide. Whether for conveyors, pumps, compressors, or mining machinery, Grid Coupling technology remains a core component of efficient and safe power transmission systems.

References

GB/T 7714:Bhandari V B. Design of machine elements[M]. Tata McGraw Hill Education Private Limited, 2010.

MLA:Bhandari, V. B. Design of machine elements. Tata McGraw Hill Education Private Limited, 2010.

APA:Bhandari, V. B. (2010). Design of machine elements. Tata McGraw Hill Education Private Limited.