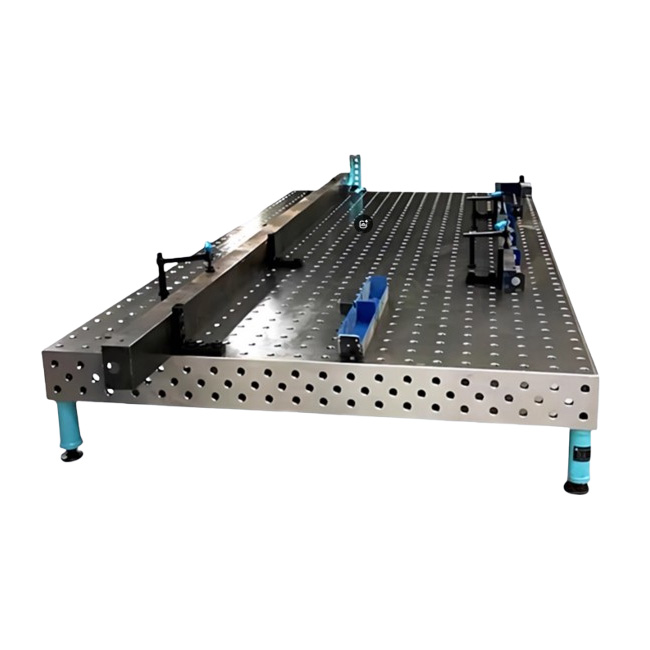

Why a Welding Table Matters in Fabrication

In metal fabrication, precision and stability determine the quality of the final product. One essential foundation for this process is the Welding Table. It provides a flat, rigid, and secure working surface that supports parts during cutting, fitting, and welding operations. Without a reliable welding table, even skilled operators struggle to maintain alignment, safety, and efficiency.

From a professional Welding Table manufacturer and factory production perspective, these tables are engineered for load capacity, thermal resistance, and dimensional stability. With scalable production and factory batch supply, Welding Table solutions support workshops, OEM production lines, and industrial fabrication facilities with consistent quality.

Understanding the true purpose of a Welding Table helps fabricators improve accuracy, workflow, and long-term productivity.

What Is a Welding Table?

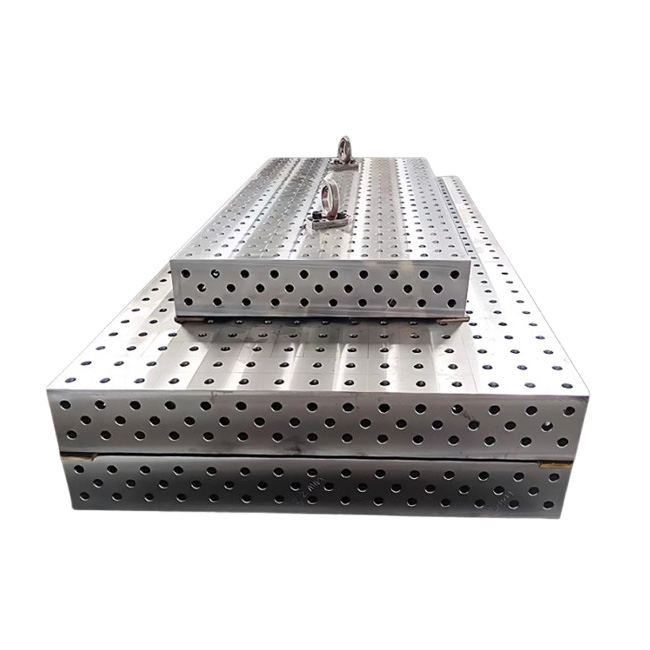

A Welding Table is a specially designed work surface used to hold, position, and support metal components during fabrication processes such as welding, grinding, and assembly. Unlike standard benches, a welding table is built to resist heat, impact, and mechanical loads.

Key characteristics include:

·Flat and rigid structure

·High load-bearing capacity

·Heat and spark resistance

·Fixture and clamping compatibility

·Long-term dimensional stability

During professional manufacturer production, tables are machined, welded, and finished to tight tolerances. Advanced factory production processes ensure uniform flatness and surface strength across batch supply.

Core Purpose of a Welding Table

The purpose of a Welding Table goes beyond simply holding materials. It directly affects fabrication quality and efficiency.

Providing Accurate Positioning

Precision is critical in fabrication. A Welding Table provides a reference plane that ensures parts stay square and aligned.

Benefits include:

·Consistent geometry

·Reduced rework

·Better joint fit-up

With standardized factory production, table surfaces are controlled for flatness, helping maintain accuracy across multiple projects and production runs.

Supporting Clamping and Fixturing

A quality Welding Table allows operators to clamp parts securely before welding.

This enables:

·Stable workholding

·Reduced movement during welding

·Repeatable setups

During manufacturer production, hole patterns and surface structures are designed to accept modular fixtures, improving flexibility in fabrication environments.

Improving Safety in the Workshop

Welding involves heat, sparks, and heavy materials. A stable Welding Table improves operator safety.

Safety advantages include:

·Reduced risk of part shifting

·Fire-resistant surfaces

·Better control of heavy assemblies

With durable factory production materials, tables withstand thermal shock and mechanical stress, protecting both operators and equipment.

Enhancing Productivity

Efficiency matters in any fabrication shop. A proper Welding Table improves workflow and reduces setup time.

Productivity gains include:

·Faster part alignment

·Less repositioning

·Improved repeatability

From a manufacturer production standpoint, standardized dimensions and modular compatibility allow tables to integrate smoothly into production lines and batch fabrication systems.

Structural Design and Materials

The performance of a Welding Table depends heavily on its construction.

Common design features include:

·Heavy-duty steel frames

·Machined or plasma-cut surfaces

·Reinforced legs and supports

·Heat-resistant coatings

During factory production, CNC machining, welding, stress relieving, and surface finishing ensure dimensional stability and durability.

Quality checks verify:

·Flatness tolerance

·Load capacity

·Weld integrity

·Surface hardness

Reliable production and factory batch supply ensure every Welding Table meets industrial performance standards.

Thermal and Mechanical Stability

Welding generates localized heat that can distort surfaces. A high-quality Welding Table minimizes deformation and maintains accuracy.

Thermal advantages include:

·Heat dissipation capability

·Resistance to warping

·Stable geometry over time

Through controlled manufacturer production, materials and structural ribs are optimized to balance strength and thermal behavior, ensuring stable operation even in high-duty cycles.

Installation and Shop Layout Benefits

A Welding Table also improves workshop organization and layout.

Installation advantages include:

·Modular positioning

·Adjustable leveling

·Space-efficient configuration

With standardized factory production, tables arrive ready for integration into fabrication cells, robotic welding lines, and manual assembly stations.

This supports consistent production flow and reduces downtime during layout changes.

Applications in Fabrication

The purpose of a Welding Table applies across many fabrication fields, such as:

·Structural steel fabrication

·Automotive body welding

·Machinery assembly

·Industrial equipment production

·Metal framework construction

With scalable factory production capability, Welding Table designs can be customized for size, load rating, and fixture compatibility to meet different fabrication requirements.

Manufacturing Capability and Batch Supply

From a supply viewpoint, stable performance begins at the factory. Professional Welding Table manufacturer production includes:

Precision machining

·Robotic welding

·Surface stress relief

·Load testing

·Dimensional inspection

With large-scale factory batch supply, high-volume orders maintain consistent flatness and strength for OEM and industrial customers. Strong production systems ensure traceability, durability, and long service life.

Lifecycle Cost and Reliability

While a basic bench may cost less initially, a professional Welding Table provides better long-term value.

Lifecycle benefits include:

·Longer service life

·Reduced rework

·Improved weld quality

·Lower maintenance cost

From a manufacturer production perspective, investing in material quality and process control lowers failure risk and improves overall fabrication efficiency.

Conclusion: The Real Purpose of a Welding Table

The Welding Table is the foundation of accurate, safe, and efficient fabrication. It supports positioning, clamping, safety, productivity, and thermal stability in welding operations.

By selecting solutions produced through professional Welding Table manufacturer production with advanced factory batch supply capability, users gain consistent performance, higher weld quality, and long-term operational reliability.

With strong production and factory systems, the Welding Table continues to play a vital role in modern fabrication environments.

References

GB/T 7714:Kalpakjian S. Manufacturing processes for engineering materials[M]. Pearson Education India, 1985.

MLA:Kalpakjian, Serope. Manufacturing processes for engineering materials. Pearson Education India, 1985.

APA:Kalpakjian, S. (1985). Manufacturing processes for engineering materials. Pearson Education India.